Data Integration Platform

Seamless Data and Application Integration With Lobster.

Bring your data together like never before. With Lobster. Our data integration capabilities seamlessly link all your data sources and applications – quickly and efficiently. Experience true data harmony.

6 Good Reasons for Data Integration With Lobster.

Lorem ipsum.

One Platform for All Your Integrations.

Say goodbye to data silos. With Lobster, everything comes together on one platform — integrating all your data sources and business applications seamlessly.

Minimal Effort, Maximum Integration.

Stop wasting time on complex coding. Lobster’s no-code solution, packed with ready-made connectors, lets you integrate your data and applications effortlessly into existing systems.

All Formats and Protocols. Covered.

From XML to JSON, CSV to EDIFACT, Lobster handles all common formats. With support for protocols like HTTP, FTP, and AS2, you’ll never worry about compatibility again.

Headline 3-Grid Boxes

Lorem ipsum dolor sit amet consectetur. Gravida lorem aenean libero at sit iaculis volutpat. Sit vestibulum cursus accumsan risus.

Uncompromising Security.

Protect your data with cutting-edge security features like OAuth 2.0, SSO, 2FA, MFA, and LDAP. With Lobster, your data is always in safe hands.

Infinite Scalability and Flexibility.

Whether you’re integrating two data sources or two thousand, Lobster scales effortlessly to meet your growing needs.

Flexible Deployment Options.

Choose the setup that works for you: on-premises, Lobster Cloud, private cloud, or a hybrid solution.

Configure Over Code.

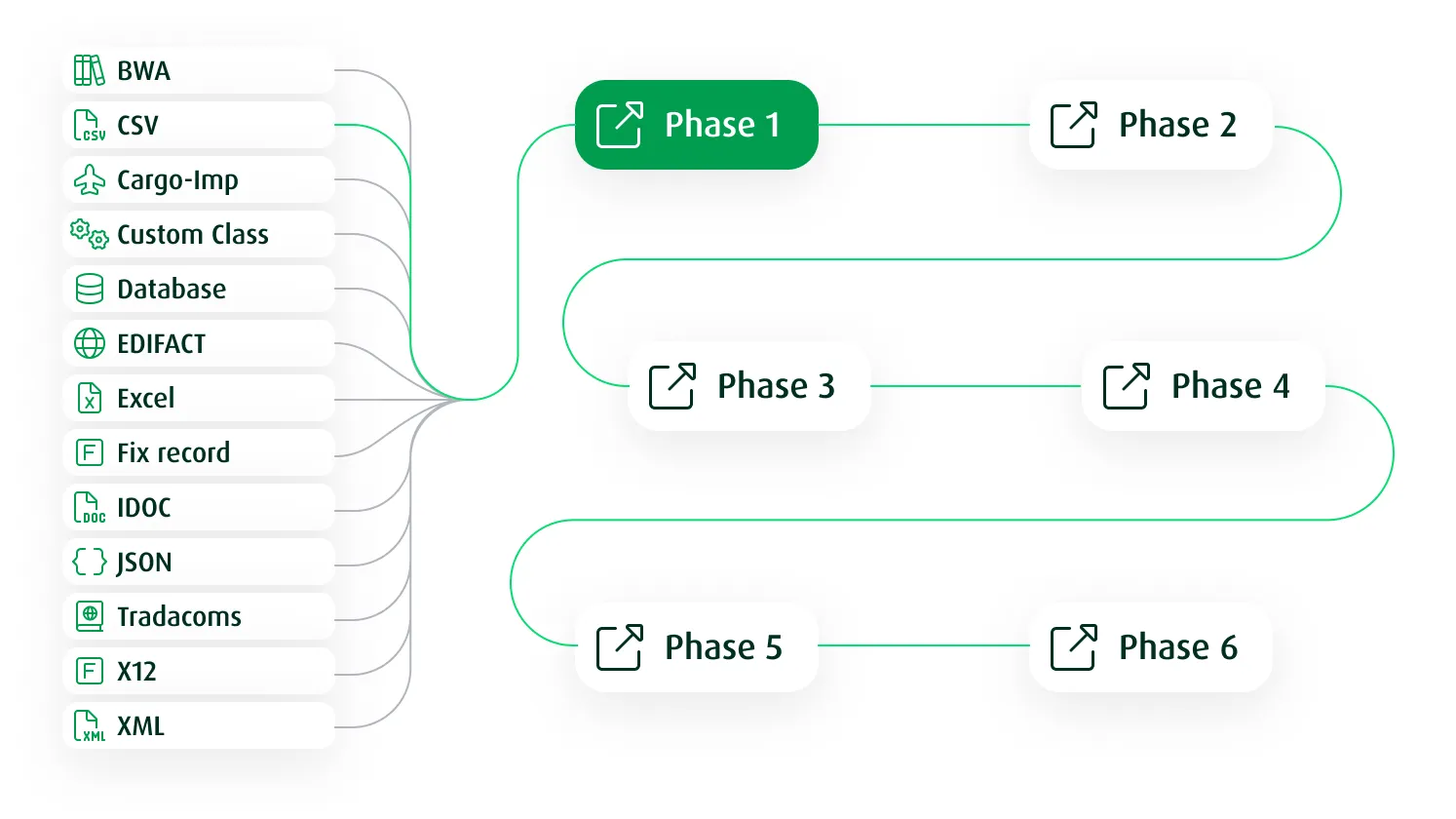

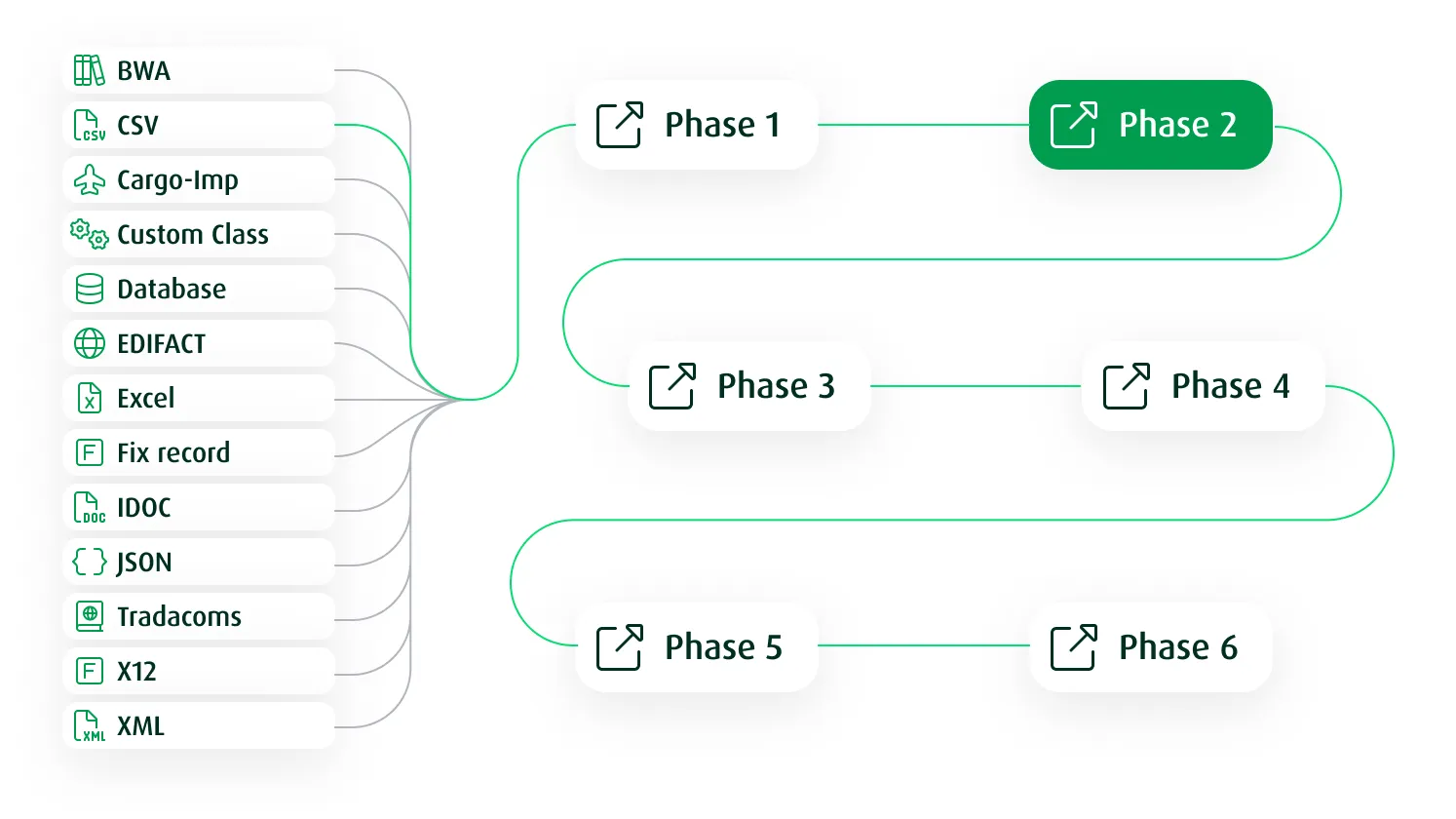

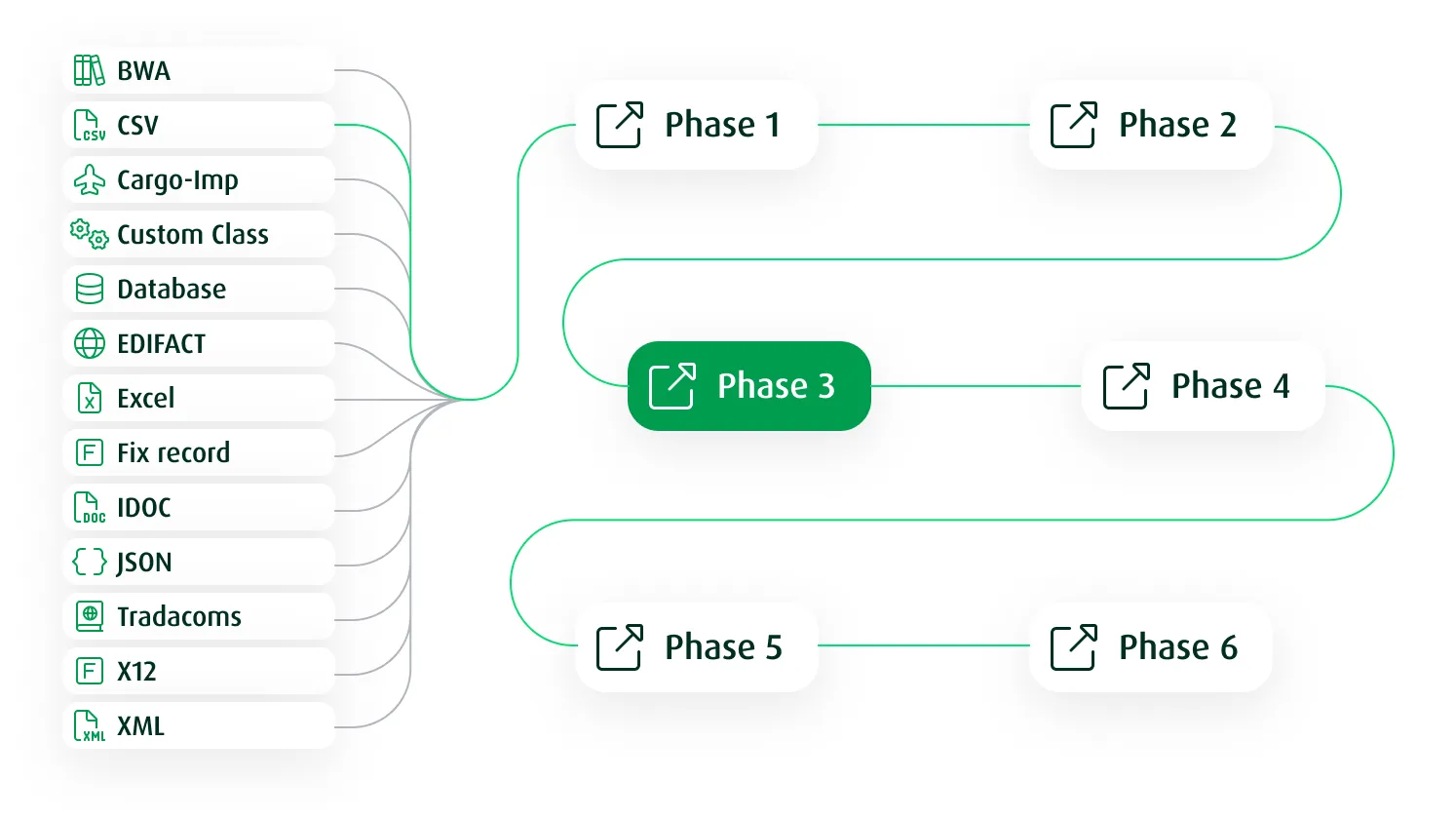

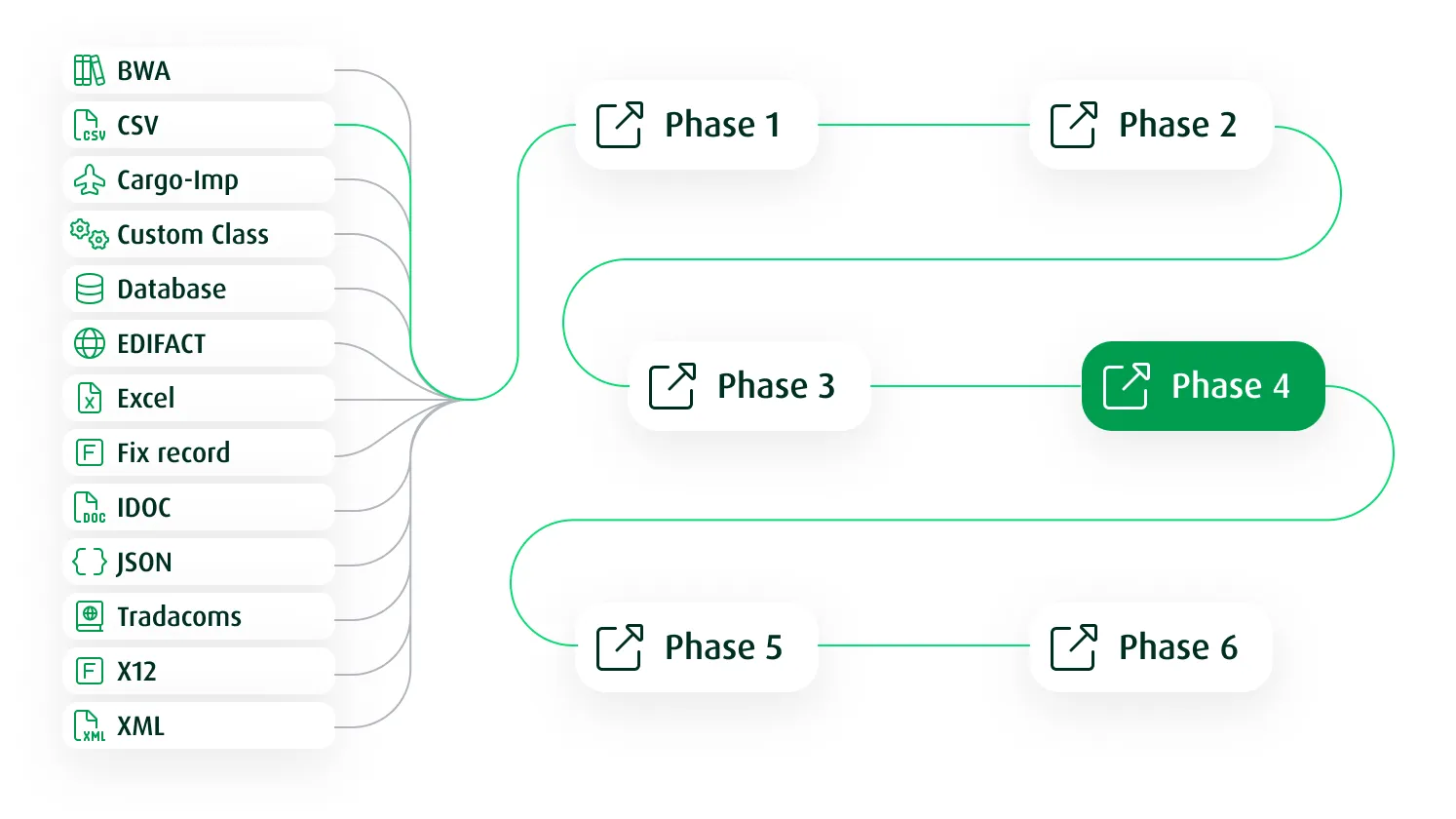

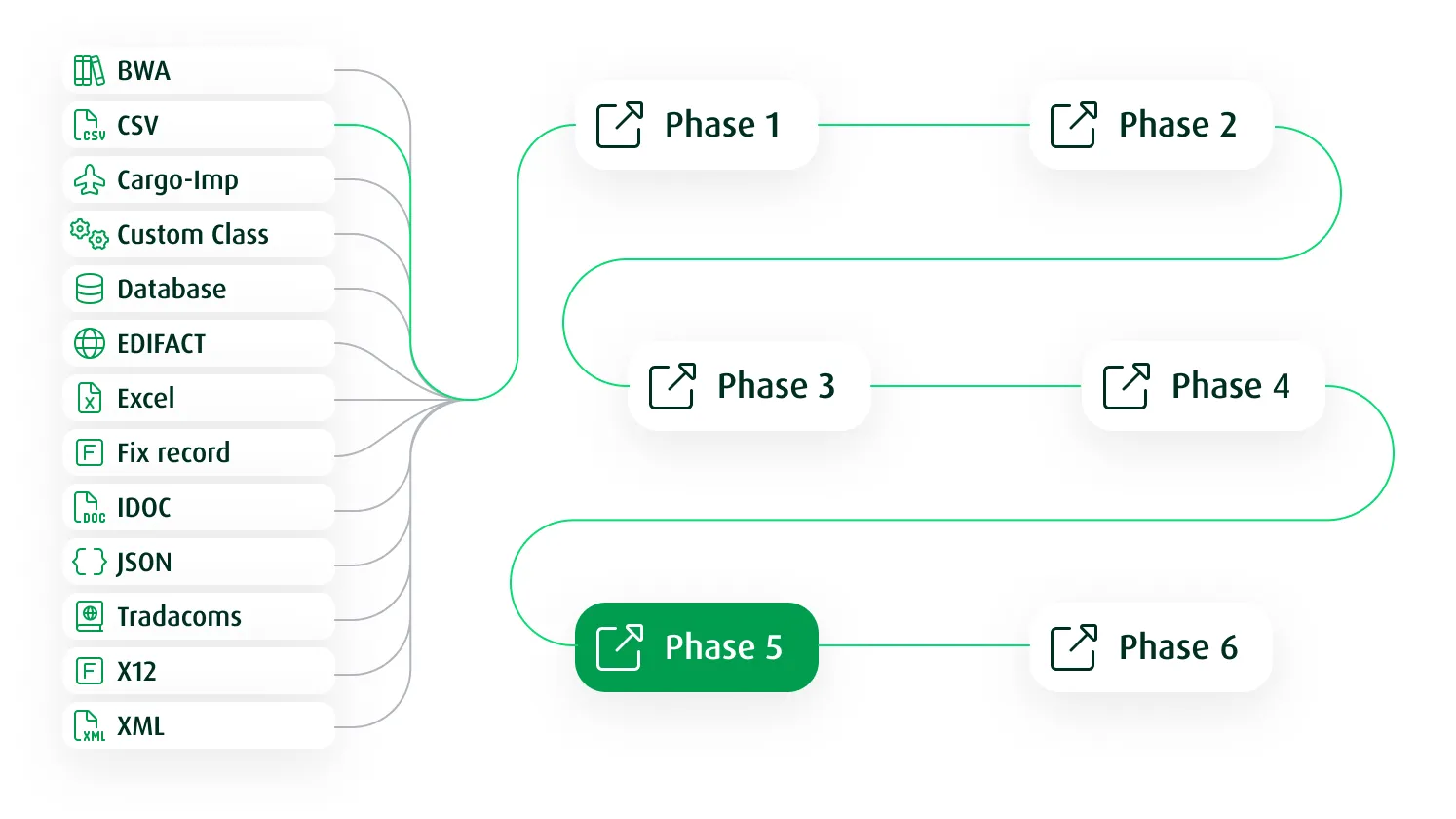

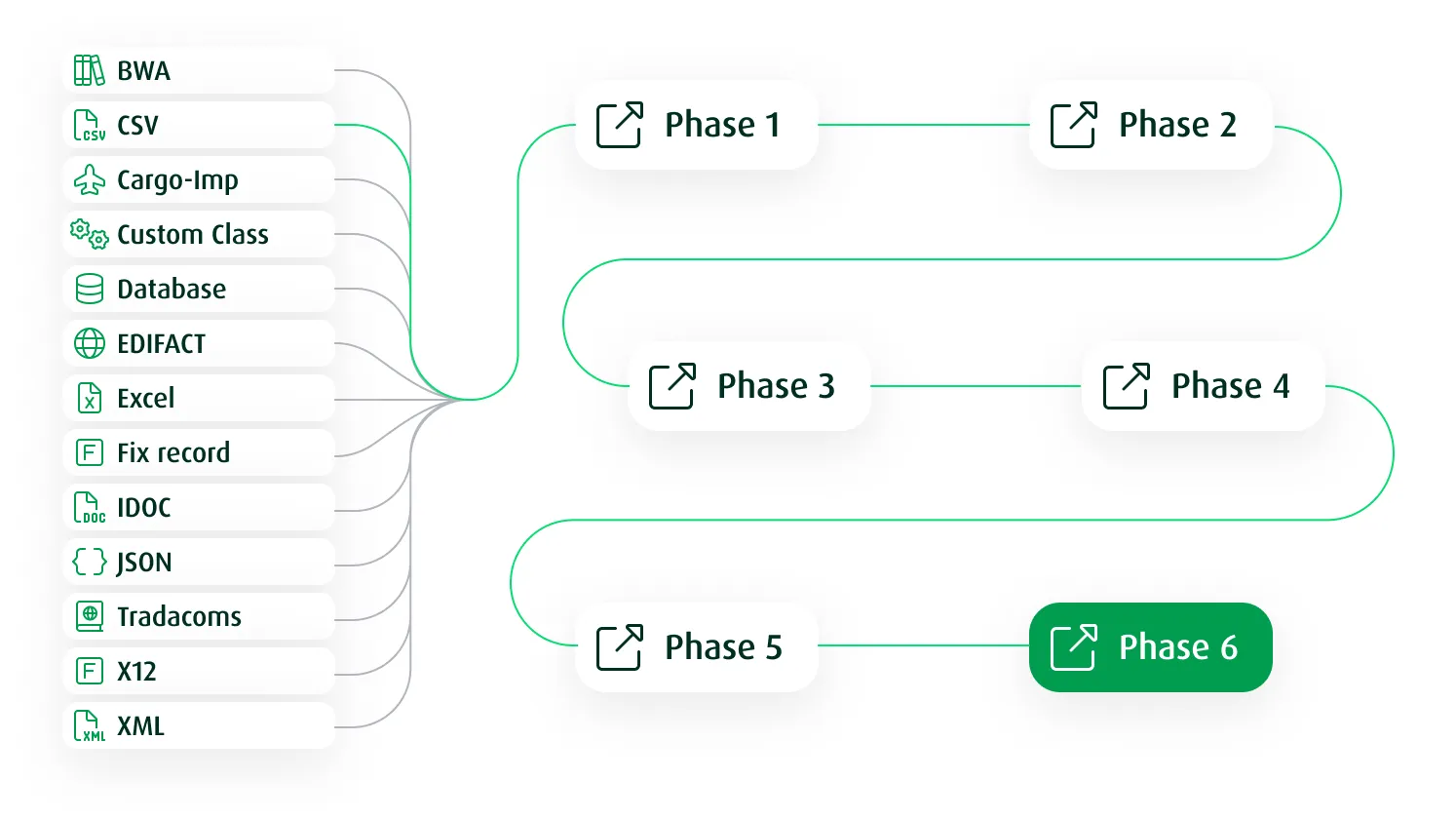

Easily integrate your data and business applications without a single line of coding. Drag, drop, and standardise integration workflows with Lobster’s intuitive 6-phase model.

Item #1

Lorem

Efficient Data & Application Integration.

In 6 Simple Steps.

Integrate all data with Lobster’s unique, standardised 6-phase model. Powered by user-friendly drag & drop. Learn more about the 6-phase approach here:

Headline Tabs

Phase 1: Receiving Data.

Receive data from local or remote systems, whether through time-controlled retrieval or active data pushes. Supported protocols include FTP(S), SFTP, HTTP(S), AS2, WebService, and more.

Phase 2: Reading Data.

Choose the right parser – CSV, XML, or others –and define input structures with ease. Simplify processing using functions like space removal.

Phase 3: Processing Data.

Create target structures and configure mappings with drag-and-drop tools. Use over 450 built-in functions to transform, validate, and enrich your data.

Phase 4: Outputting Data.

Shape your data into the desired formats. Generate PDFs, EDIFACT files, or Excel documents, and manage default settings centrally for consistency.

Phase 5: Sending Data.

Distribute messages through various channels like FTP(S), HTTP(S), AS2, or SMTP. Set dispatch conditions and escalation scenarios to suit your needs.

Phase 6: Monitoring and Notifications.

Keep an eye on every process in the centralised Control Centre. Get automatic alerts for errors and intervene when necessary.

Trusted by Over 2,000 Companies.

Here are their experiences.

Torsten Frantz

“We chose Lobster because the mapping is so transparent and easy to use. It’s really true that what you see is what you get.”

Steen Jungdal

“The price per integration is very competitive. When you break it down by the cost of each individual integration – including the license fee, the resources on our on-prem server, and the expenses for development and deployment – it really adds up in our favour.”

Abderrahim Wahabi

“Lobster’s Data Platform guarantees that everyone involved gets the information they need, in the right format, so they can keep things moving smoothly. We were really impressed by how versatile and reliable the software is.”

Best-in-Class Solutions.

Customers love Lobster – and the proof is in the rankings. G2 reports consistently rate us as a top performer.

Data and Application Integration.

In 3 Easy Steps.

Lorem ipsum dolor sit amet consectetur. Gravida lorem aenean libero at sit iaculis volutpat. Sit vestibulum cursus accumsan risus.

Get in Touch.

Tell us what you need. Together, we’ll find the right integration approach for you.

Join the Revolution.

Whether you’re a DIY enthusiast or prefer expert support, nothing stands in the way of seamless integration.

Numbers Speak Louder Than Words. The Lobster Data World Simply Adds Up.

Item

More Data Processed Daily.

Item

Cost Savings.

Item

Faster Time to Market.

Let's Talk.

So Much More Than Data Integration.

With Lobster, you’re not just integrating data – you’re revolutionising how you connect and control it.

Do Away With Data Silos. Connect & Integrate.

No matter where your data resides, Lobster will help you connect and combine it. Say goodbye to disparate, disjointed data and hello to transparent information flows that foster success.

Propel Your Business.

Process Automation.

Eliminate the errors and delays of manual data entry with process automation. For streamlined workflows, no more redundancy and more time to focus on what truly matters.

Streamline Your Supplier Relationships.

Unlock collaborative planning, forecasting, and replenishment and see how easy supplier relationship management can be. Think rapid onboarding, performance monitoring and real-time data exchange.

Lorem Ipsum Dolor

Lorem ipsum dolor sit amet consectetur. Vitae eget tempus risus erat aliquet. Morbi non sit orci vitae eu enim. Sed dui sed turpis diam consectetur velit nec morbi. Blandit nec bibendum euismod eu.

Good Questions, Already Answered.

What does Lobster cost?

Lobster’s pricing is tailored to your needs. Choose from different editions and enhance functionality with optional packages. We’ll create a custom quote based on your requirements.

How does Lobster ensure data security?

Your data’s safety is our priority. Lobster uses advanced security protocols like OAuth 2.0, SSO, and 2FA. Plus, the platform is ISO 27001 and ISO 27018 certified for top-tier security.

How quickly can Lobster be implemented?

On average, implementation takes less than 24 days. With our expert guidance, you’ll be up and running in no time.

Is Lobster suitable for all businesses?

Absolutely. Lobster fits companies of any size or industry that want to harness the power of data.

What deployment options does Lobster offer?

You decide: use Lobster on-premises, in the Lobster Cloud, in your private cloud, or with a hybrid setup.